Added: Jan 07, 2026

Last edited: Jan 07, 2026

Fiber Laser Market: Growth, Trends, and Forecast (2026–2034)

The global fiber laser market is expected to witness strong growth during the forecast period, driven by increasing demand for high-precision manufacturing, automation, and advanced material processing across industries such as automotive, electronics, aerospace, medical devices, and renewable energy. The market was valued at USD 4.63 billion in 2025 and is projected to grow from USD 5.18 billion in 2026 to USD 13.08 billion by 2034, registering a CAGR of 12.3%.

Fiber Laser Market Overview

Fiber lasers are solid-state lasers that use optical fibers doped with rare-earth elements such as ytterbium, erbium, or neodymium as the gain medium. These lasers are widely preferred due to their high beam quality, superior energy efficiency, long operational life, compact size, and low maintenance costs. Their ability to deliver precise and consistent performance makes them ideal for both industrial and non-industrial applications.

Download Free Sample: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/fiber-laser-market-110915

Key Market Drivers

Rising Demand for Precision Material Processing

The growing adoption of fiber lasers in cutting, welding, marking, and engraving applications is a major factor fueling market growth. Industries such as automotive and aerospace increasingly rely on fiber lasers to enhance productivity, reduce material wastage, and improve manufacturing accuracy.

Expansion of Electric Vehicle Manufacturing

The rapid growth of the electric vehicle industry has significantly boosted the demand for fiber lasers. These lasers play a critical role in battery welding, lightweight material processing, and high-precision component manufacturing required for EV production.

Industrial Automation and Smart Manufacturing

The integration of fiber laser systems with automation, robotics, and digital manufacturing technologies has improved production efficiency and quality control. This trend is accelerating the adoption of fiber lasers across smart factories and Industry 4.0 environments.

Fiber Laser Market Segmentation

By Type

Continuous Wave Fiber Lasers

This segment holds the largest market share due to its extensive use in continuous industrial operations such as metal cutting and welding.

Pulsed Fiber Lasers

Expected to witness rapid growth owing to their increasing use in micro-machining, medical devices, electronics manufacturing, and precision marking applications.

By Power Output

High-Power Fiber Lasers (Above 2 kW)

Dominant in heavy-duty industrial applications including shipbuilding, automotive body welding, and thick metal cutting.

Medium-Power Fiber Lasers (100W–2kW)

Anticipated to grow at the fastest rate due to rising adoption in sheet metal fabrication, electronics, and medical equipment manufacturing.

By Application

Material Processing

The largest application segment, driven by strong demand from automotive, electronics, and industrial manufacturing sectors.

Instruments and Sensors

This segment is gaining traction due to increasing use in spectroscopy, sensing, measurement, and monitoring applications.

Regional Market Insights

Asia Pacific

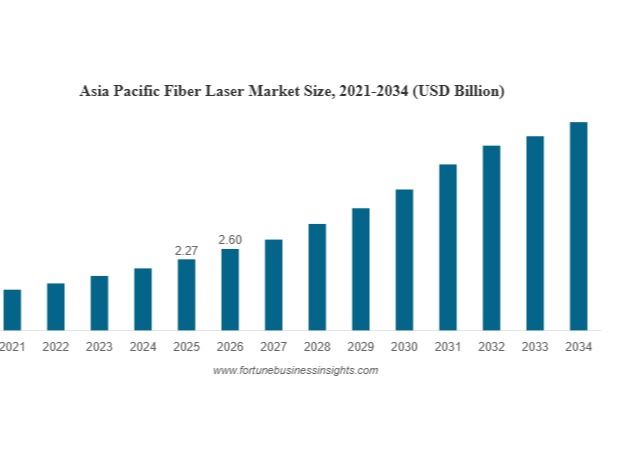

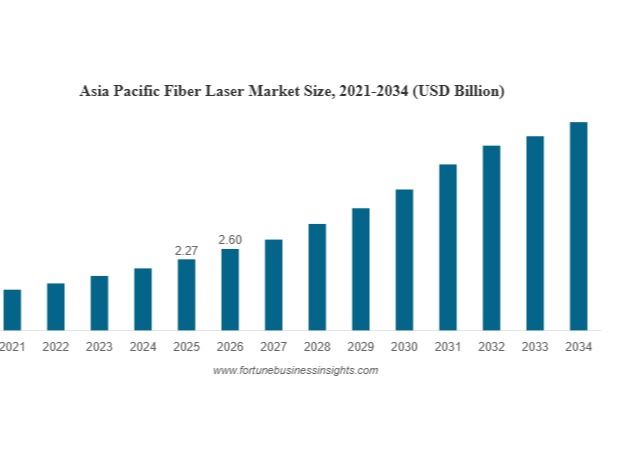

Asia Pacific dominates the global fiber laser market, accounting for nearly 49% of the total market share. Rapid industrialization, strong manufacturing bases in China, Japan, South Korea, and India, and increasing investments in advanced production technologies support regional growth.

North America

The market in North America is driven by technological advancements, high adoption of automation, and strong demand from aerospace, defense, and automotive industries.

Europe

Europe shows steady growth supported by industrial modernization, automotive manufacturing, and increasing adoption of laser-based technologies.

Middle East & Africa and South America

These regions are expected to experience moderate growth due to rising infrastructure development and gradual adoption of advanced manufacturing solutions.

Market Challenges

High Initial Investment Costs

The cost of fiber laser systems and installation can be high, limiting adoption among small and medium-sized enterprises.

Availability of Alternative Technologies

Competing technologies such as CO₂ lasers and diode lasers may restrain market growth in price-sensitive applications.

Growth Opportunities

Renewable Energy and Solar Panel Manufacturing

Fiber lasers are increasingly used for precision cutting and processing in solar cell manufacturing, offering new growth opportunities.

Medical and Electronics Applications

Growing demand for minimally invasive medical devices and compact electronic components is expected to create lucrative opportunities for pulsed fiber lasers.

Competitive Landscape

The fiber laser market is highly competitive, with leading companies focusing on innovation, product expansion, and strategic collaborations. Key players include:

IPG Photonics

Coherent

TRUMPF

nLIGHT

Fujikura

Lumentum Holdings

Wuhan Raycus

Han’s Laser Technology

These companies are actively investing in research and development to enhance laser power, efficiency, and integration with automated systems.

Conclusion

The fiber laser market is poised for robust expansion from 2026 to 2034, driven by rising industrial automation, electric vehicle production, and demand for precision manufacturing. With strong growth across Asia Pacific and increasing adoption in advanced industries worldwide, fiber lasers are expected to remain a key technology shaping the future of modern manufacturing.

Information Source: https://www.fortunebusinessinsights.com/fiber-laser-market-110915

KEY INDUSTRY DEVELOPMENTS:

October 2024: nLIGHT launched two new laser technologies, Automatic Parameter Tuning (APT) and WELDForm, aimed at enhancing battery manufacturing quality. These innovations were showcased at The Battery Show North America.

September 2024: Bodor launched an upgraded M Series laser cutting machine featuring Dual Process Parallel Processing, allowing simultaneous tube cutting and loading/unloading to enhance productivity. This innovative system and its four-chuck design offer five cutting modes, targeting various tube weights and lengths while ensuring zero waste material cutting.