Added: Oct 28, 2025

Last edited: Oct 28, 2025

According to Fortune Business Insights, The global aluminum forging market was valued at USD 3.94 billion in 2024 and is expected to grow from USD 4.07 billion in 2025 to USD 5.12 billion by 2032, exhibiting a CAGR of 3.32% during the forecast period (2024–2032).

Aluminum forging refers to a manufacturing process that shapes aluminum through the application of compressive force at high temperatures. During this process, aluminum is heated until it becomes malleable and then pressed or hammered into the required form using molds or dies. This technique produces components with enhanced strength, durability, and dimensional accuracy compared to those made by casting or machining. The market growth is primarily fueled by rising demand across automotive, aerospace, and construction industries, driven by aluminum’s lightweight, high-strength, and corrosion-resistant properties.

Aluminum forging is a manufacturing process that enhances the strength, durability, and reliability of aluminum components by shaping them under high pressure. The process is widely used to produce high-performance parts for critical applications where lightweight yet strong materials are essential.

Request a FREE Sample Copy: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/aluminum-forging-market-109544

Key Market Drivers

1. Growing Demand in Automotive and Aerospace Industries

The rapid expansion of the automotive industry, particularly the shift toward electric and lightweight vehicles, has significantly boosted aluminum forging demand. Forged aluminum parts reduce overall vehicle weight, improving fuel efficiency and performance.

Similarly, in the aerospace sector, forged aluminum components are preferred for structural parts due to their high strength-to-weight ratio, corrosion resistance, and fatigue performance.

2. Focus on Lightweight and Sustainable Materials

As sustainability becomes a central theme across industries, aluminum forging offers an eco-friendly manufacturing alternative. Aluminum’s recyclability and lower carbon footprint compared to steel have made it an ideal choice for green manufacturing initiatives.

3. Technological Advancements in Forging Processes

The adoption of advanced forging techniques such as precision forging, isothermal forging, and computer-aided process simulation has enhanced productivity and reduced material wastage. These innovations have improved dimensional accuracy, making aluminum forging suitable for complex applications in defense, aerospace, and industrial machinery.

Market Segmentation

By Type

Open Die Forging

Closed Die Forging

Rolled Ring Forging

By Application

Automotive

Aerospace

Industrial Equipment

Defense

Others

By Region

North America: Dominates the global market due to strong aerospace and defense manufacturing base.

Europe: Major growth driven by sustainable automotive production and technological innovation.

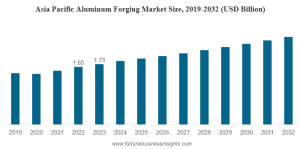

Asia Pacific: Expected to exhibit the fastest growth due to expanding automotive manufacturing in China, India, and Japan.

Regional Insights

Asia Pacific held a significant share in 2023 and is projected to continue its dominance through 2032. The region’s large-scale automotive production, coupled with rapid industrialization, supports market expansion. China and India are the leading contributors, with increasing investments in lightweight manufacturing and export-oriented production.

North America is another crucial market, supported by advanced aerospace production in the U.S. and strong demand for high-performance materials. The region’s technological leadership in forging processes also supports growth.

Competitive Landscape

The aluminum forging market is moderately fragmented, with leading players focusing on strategic expansions, mergers, and product innovations. Key companies are investing in automation and digital forging technologies to enhance precision and sustainability.

Major Companies in the Aluminum Forging Market Include:

Arconic Corporation

Otto Fuchs KG

Bharat Forge Limited

thyssenkrupp AG

CFS Forge

Anchor Harvey Components

KOBELCO

Alcoa Corporation

Trenton Forging

Recent Developments

Arconic Corporation expanded its forged components business to support growing demand from EV manufacturers.

Bharat Forge Limited announced investments in green forging technologies to reduce emissions and energy consumption.

Otto Fuchs KG introduced new high-strength aluminum alloy forgings for aerospace applications.

Information Source: https://www.fortunebusinessinsights.com/aluminum-forging-market-109544

Future Outlook

The future of the aluminum forging market looks promising, with continuous advancements in material science and forging technologies. Increasing adoption in EV manufacturing, defense modernization, and renewable energy infrastructure will further accelerate market expansion.

As industries move toward lightweight, energy-efficient, and recyclable materials, aluminum forging will remain a vital process supporting global sustainability goals.

The aluminum forging market is set to grow steadily over the next decade, driven by technological innovation, sustainability initiatives, and rising industrial applications. With strong demand across automotive, aerospace, and industrial sectors, manufacturers are focusing on enhancing production efficiency and forging capabilities to meet evolving market needs.