Approved by curator

Added: Sep 17, 2021

Last edited: Oct 01, 2021

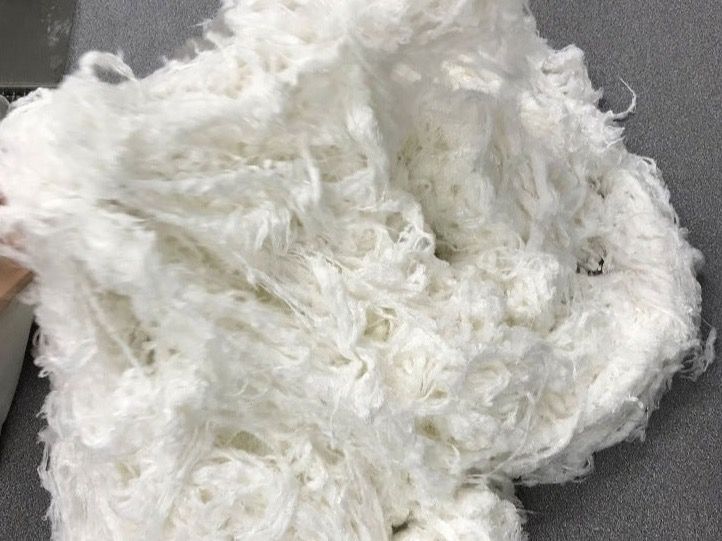

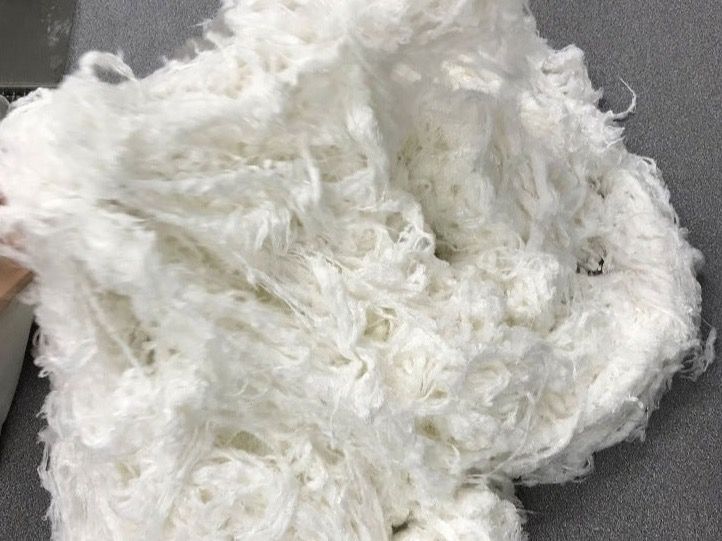

Nanollose developed Nullabor Fibre, which is a rayon fibre produced from microbial cellulose grown on liquid organic industrial waste and agricultural waste.

The production of man-made cellulose fibre is often associated with endangering ancient forests and the use of irrigation, pesticides and other resource-intensive inputs connected to trees plantations. An intensive purification process is needed to extract the cellulose required for rayon production. The cellulose extracted is then regenerated into fibres that make fabrics called rayon/viscose that primarily go into making clothes.

Microbial cellulose offers a sustainable alternative solution to cellulose derived from trees. Moreover, Nanolllose uses feedstock waste to produce microbial cellulose. It has created the world’s first wearable garment using its Tree-Free Rayon fibre (Nullarbor), sourced from sustainable coconut waste.

Nanollose’s waste-to-clothing technology has created a tree-free rayon fibre named Nullabor that is easily retrofitted into current textile and clothing production methods.

Nanollose Executive Chairman Wayne Best said, “We have successfully taken waste and created clothing, and we have done it following industrial protocol. Our fibre was spun into yarn and made into fabric, then manufactured into this garment using existing industrial equipment. It validates our entire process.”

150 million trees are cut down each year, then chipped and treated with hazardous chemicals to extract the raw material used to make Viscose Rayon fibres for clothing. By contrast, Nanollose’s Nullarbor fibre is made without harming a single tree.

“We didn’t have to cut down any trees to create this sweater, and we have now demonstrated that our Tree-Free Rayon fibre can be used in the same way as other commonly-used fibres to make clothing and textiles, without the hefty environmental footprint.” Mr Best said

agricultural waste

cellulose

Man Made Cellulose Fibres

Cellulose based textiles

microbial cellulose

industrial waste

rayon